#205Compost

205⸱AConcept

- Improves soil structure and organic matter

- Improves soil life

- Improves plant nutrition

- Increases the coffee yield

Compost is used in addition to or instead of mineral fertilizers. It improves soil fertility, soil structure, and plant nutrition, and increases the humus content in the soil over time.

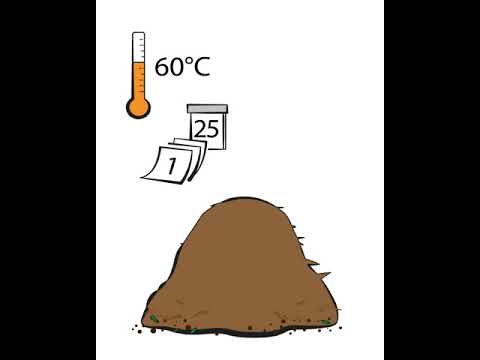

It is produced through a process called composting. Composting is a biological process in which organic material is decomposed by microorganisms. It occurs under aerobic conditions (presence of oxygen). With adequate humidity and temperature, it ensures a hygienic transformation of organic waste into a homogeneous material that is an excellent source of nutrients for the soil and brings life to the production system through the beneficial microorganisms it contains.

Its composition varies according to the type and quantity of materials used in its production. At the simplest level, the process of composting requires making a heap of wet organic matter such as leaves, grass, and vegetable residues, and waiting for the materials to break down into compost during a few months. In the context of coffee growing, the main ingredients for making compost are coffee husks and manure, preferably cow or chicken manure. Other plant materials, such as farm and kitchen waste can also be used. The composting process takes 3-4 months.

Over time, compost is expected to improve the efficiency of the use of conventional fertilizers and reduce the need to apply them. This is because compost, if well managed, can help reduce losses of nutrients and keep them more available in the soil for the coffee tree. The lower demand for conventional fertilizers will make the practice of applying organic compost economically viable and improve the quality and health of the soil.

It improves the soil structure so that coffee plant roots can easily reach down into the soil. In sandy soil the compost and the resulting humus make the sand particles stick together. This reduces the size of the spaces (pores) so that water stays longer in the soil. In clay soils, the compost surrounds the clay particles making more spaces (pores) in the soil so the root systems of plants can reach the water and nutrients that they need, and air can also move through the soil. Therefore, as heavy clay soils become lighter and sandy soils become heavier, soil that has had compost added to it is easier to work, i.e. to plough and dig. At the same time, compost helps the soil resist erosion by water and wind. This is because water can enter the soil better and rain showers cannot build up into a flood. Soil held together with compost and eventually humus cannot be blown away so easily by wind.

Potential soil phytopathogens and harmful plants and seeds are reduced in the composting process. This is an advantage over bringing out coffee husk directly.

205⸱BVideos

205⸱CTo be considered

In general, a soil analysis should be performed before starting the process.

The applied ratio of plant and animal waste in the compost production depends on the nutrient composition of the soil. Generally, it is recommended to mix the coffee husks and cow manure in a 3:1 ratio. If chicken manure is used, it is recommended to use 4 parts coffee husk to 1 part manure. These proportions aim to maintain a carbon/nitrogen (C/N) ratio of around 30/1 at the start of the composting process.

To increase the nutrient content and quality of the final compost and based on the soil analysis, it might be recommended to add phosphate (P) and potassium (K), e.g. in the form of rock powders or eggshells. Agricultural gypsum (calcium sulfate dihydrate CaSO4·2H2O) is recommended to reduce N losses during composting and the provision calcium (Ca) and sulfur (S). The proportion of all rock powders – if used – can reach a maximum of 20% by weight.

To speed up the composting process and improve the quality of the compost, Biochar can be added to the preparation up to a limit of 10% by weight. The time of the composting process decreases by 30% and also the required number of turnings reduces. This is because the biochar improves the aeration of the composting pile.

Another advanced form of decomposing material is the preparation of so-called Bokashi. It is a fermentation process in which a mixture of "effective microorganisms" is added to the plant material to speed up the decomposition. See the Bokashi tool for more info.

It makes sense to work together: Farmers working in groups are more likely to be able to produce large quantities of good quality compost than farmers working alone.

Timing: The total composting takes around 3-4 months. The compost production should ideally be done during the dry season as soon as the coffee husk is available after harvest and processing as it is best to use it fresh. This is around four months before a fertilization period in which the ready compost could already be applied. Compost can be applied to the coffee field every year. If fertilizer is brought out several times per year, one time can be done with compost instead of conventional fertilizer.

If compost is being applied every year, the soil should also be analyzed every year. In that way, the change in the nutrient composition can be tracked and the amount of conventional fertilizer can presumably be reduced over the years.

Applying compost requires some patience. In the first years, the effects might be not strongly visible. However, applying compost regularly leads to a higher crop production over the years.

205⸱DImplementation

Materials

Through the composting process, the amount of the preparation reduces in weight. That is why the inputs together are heavier than the final weight that is aimed for. For 1 ton (20 quintals) ready-to-use compost use:

205⸱1Preparation

205⸱2Production

It is important to put the layers of different ingredients in sequence to attain proper decomposition of the materials.

During the placement of the layers of organic material, it can be recommended to use intermediate layers of a little P and K rock powder, common lime, ash, or chemical fertilizer (urea) to make the compost richer in nutrients or to regulate the acidity and favor the development of decomposing organisms.

The heap can be stabilized by a wooden frame or with forks.

205⸱3

Hand test to test the moisture: Take a portion of manure and squeeze it in your hand. If the sample breaks (crumbles), you should wet the layer more. If a few drops appear between your fingers, the humidity is adequate. If water drips between your fingers, there is too much water. In that case, stop watering and let it dry a bit.

205⸱4

The last layer should preferably be made of plant material to better protect the preparation against rainwater, although the compost production should ideally be done during the dry season. The light plant material on top ensures a better breathability than closing with the more dense manure.

205⸱5

205⸱6

When turning over the heap:

Hand test to test the moisture: Take a portion of compost and squeeze it in your hand. If the sample breaks (crumbles), you should wet the pile more. If a few drops appear between your fingers, the humidity is adequate. If water drips between your fingers, you should turn the pile to aerate it, as there is too much water.

Iron bar test to test the temperature: Insert a bar 40 cm into the middle of the pile and leave it there for a few minutes. Hold the bar with your hand, carefully, as it will be hot. If you can't hold it, turn the pile to increase aeration. If it is relatively cold (very easy to hold by hand), wet the pile more.

If it rains at some point in the 3-4 months of the composting process, the pile should be covered with a plastic tarp if available to avoid that the nutrients are washed away.

205⸱7

205⸱8Application

Generally, a soil analysis should be carried out to determine the correct amount to be applied, depending on the soil's nutritional demand.

If preparing a fresh coffee field for the plantation of new seedlings:

- In the new coffee field, it is recommended to use 10 t/ha (200 quintals/ha) when preparing the furrow and a further 2 t/ha (40 quintals/ha) on the surface after planting. It should be 1-2 kg (2 to 3 libras) per coffee plant.

- When the compost is put in the field, it should be covered quickly by soil, so the sun and wind do not damage it, and the nitrogen does not escape to the atmosphere. Therefore, it is best to put compost on the field just before ploughing, or at the same time as sowing the crop.

- For row-planted crops, it can be put in the furrow with the seed. For transplanted crops, it can be put in the hole with the seedlings.

205⸱9

If applying to existing coffee plants in a field:

- In the existing coffee field, it should be between 7 to 8 t/ha (140-160 quintals/ha) on the surface. Over the years, the applied amount can be reduced down to 5 t/ha (100 quintals/ha). It should be 250 grams (8 ounces) per coffee plant.

- The compost can be brought out on top of the soil between the coffee plants. It should be done early in the morning or late in the afternoon.

- It should be covered quickly by soil, so the sun and wind do not damage it, and the nitrogen does not escape to the atmosphere. Then you can proceed as normal with fertilizing with conventional mineral fertilizers, as recommended according to the soil analysis.

205⸱10

Coffee nursery:

- Used as a substrate for the production of seedlings, it can be mixed with the potting soil up to a maximum of 10-30 % of the mixture.

205⸱11

If applying to other crops:

- Of course, compost can also be applied to other crops than coffee.

- For row-planted crops, e.g. maize, sorghum, or vegetables, the compost can be put along the row with the seeds or seedlings.

Storage

The compost should ideally be applied directly after the preparation.

If this is not possible, the compost should be stored protected from sun and rain, covered with leaves or soil, a plastic tarp or bagged, to prevent the nutrients from escaping to the atmosphere and to avoid contamination.

Dry and covered like that, it can be stored for several weeks without deteriorating.

205⸱EEconomic benefits

Lower fertilizer costs

This tool allows for a lower demand for synthetic fertilizers and therefore saves input costs over time.

Higher coffee yield

The effects of this tool can lead to a higher coffee yield and therefore a higher income.

Re-use of waste

The economic potential is particularly high if the waste products that serve as tool ingredients are produced on the farm or in the neighborhood, for example, manure from own cattle, straw or wood from the own field. Furthermore, by utilizing waste, this tool helps reduce landfill fees.

205⸱FGreen benefits

Less synthetic fertilizers needed

This tool reduces the need for syntheticfertilizers. This reduces carbon emissions and water pollution, improves soil life, and saves resources.

Re-use of waste

Reusing organic waste material in a circular economy saves resources from being discarded. This reduces the environmental load, carbon emissions, and water pollution.

Better soil life

This tool helps improve soil life (microbes, earthworms, etc.). This plays a vital role in plant nutrition and contributes to a healthy ecosystem.